HMC CAE Lab

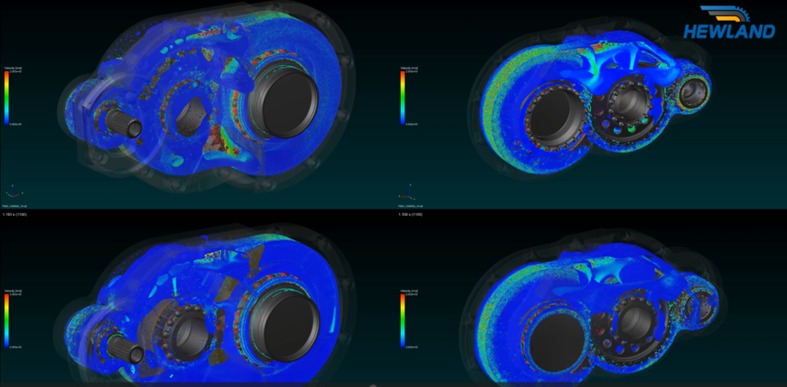

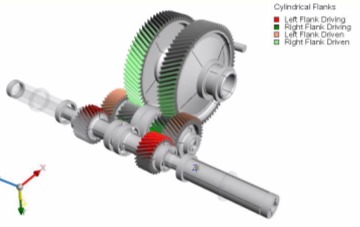

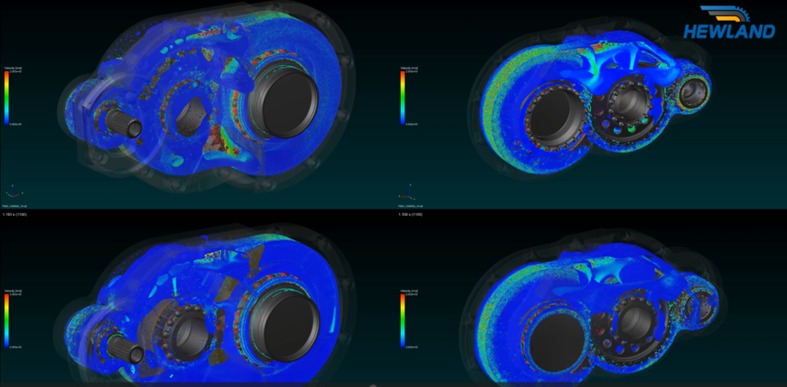

Proprietary Simulation Models v4.2

Hero Motors Company (HMC) is transforming the Aerospace & Defence ecosystem through indigenous innovation, manufacturing, and strategic partnerships.

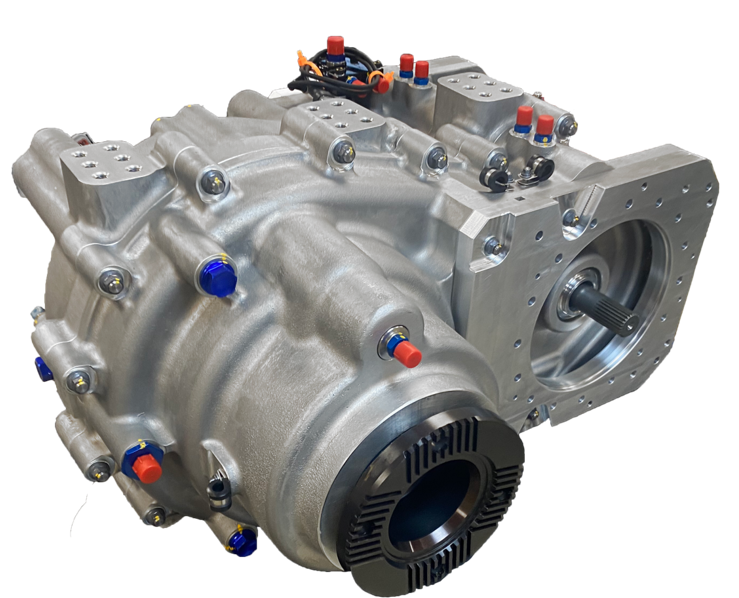

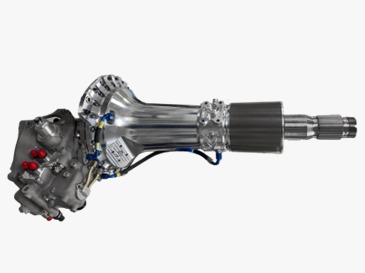

Our highly experienced engineering team develops market leading powertrain solutions via:

Proprietary Simulation Models v4.2

Our latest investment in our testing capabilities fully closes the design loop, allowing us to lead as a single-source supplier for full programme delivery.

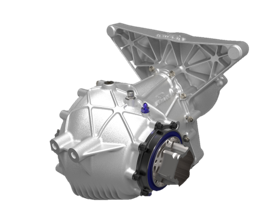

As a manufacturer of high-quality components, Hewland meets and exceeds the quality and safety thresholds for aircraft components. We currently service the following markets:

Our high-tolerance manufacturing meets and exceeds the torque and durability requirements for defence applications Our extensive experience also helps us to meet international legislative requirements for specialist and defence contexts.